Control System Suction Diffusers

To protect expensive fluid circulation equipment, industrial companies frequently install strainers on the intake side of pumps. However, many pumps are still at risk due to the turbulent flow related to the inlet side. Combine the benefits of efficient straining and effective flow conditions through suction diffusers from Denco Fluid Systems, a leading manufacturer of suction diffusers and related technologies to numerous industries.

Optimising Pump Performance with Suction Diffusers

When bringing locally sourced water into a circulation or cooling system, there is always a risk of introducing some quantity of foreign particulates. To get around this, strainer technology is mounted on the inlet side of the pump to prevent contaminants from entering.

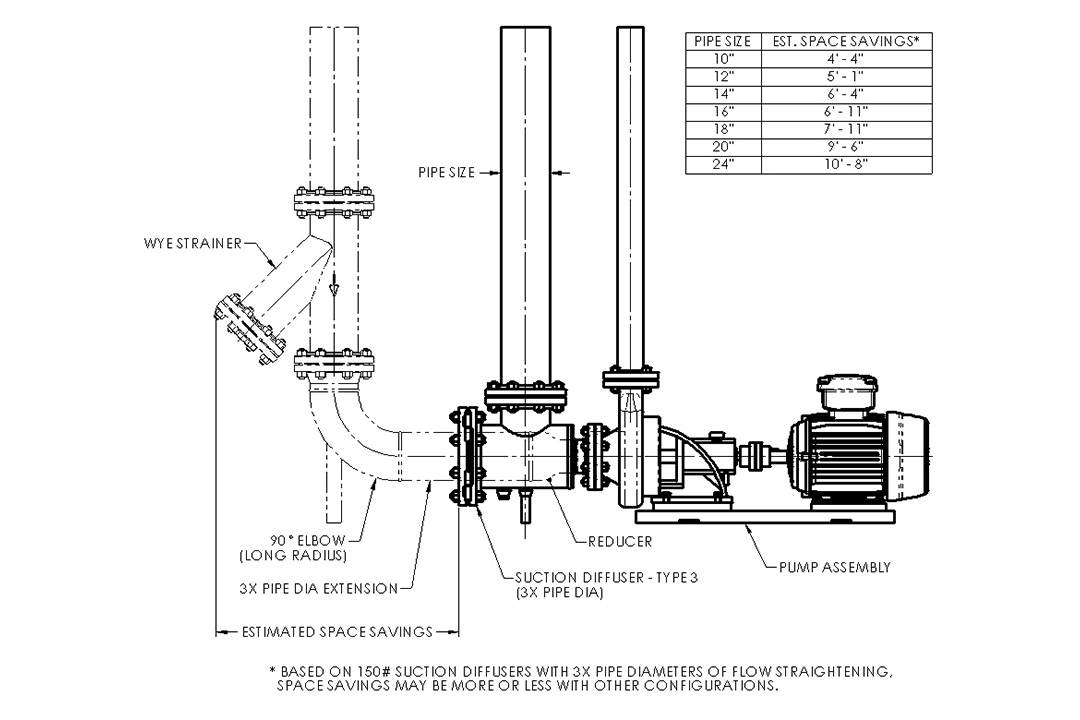

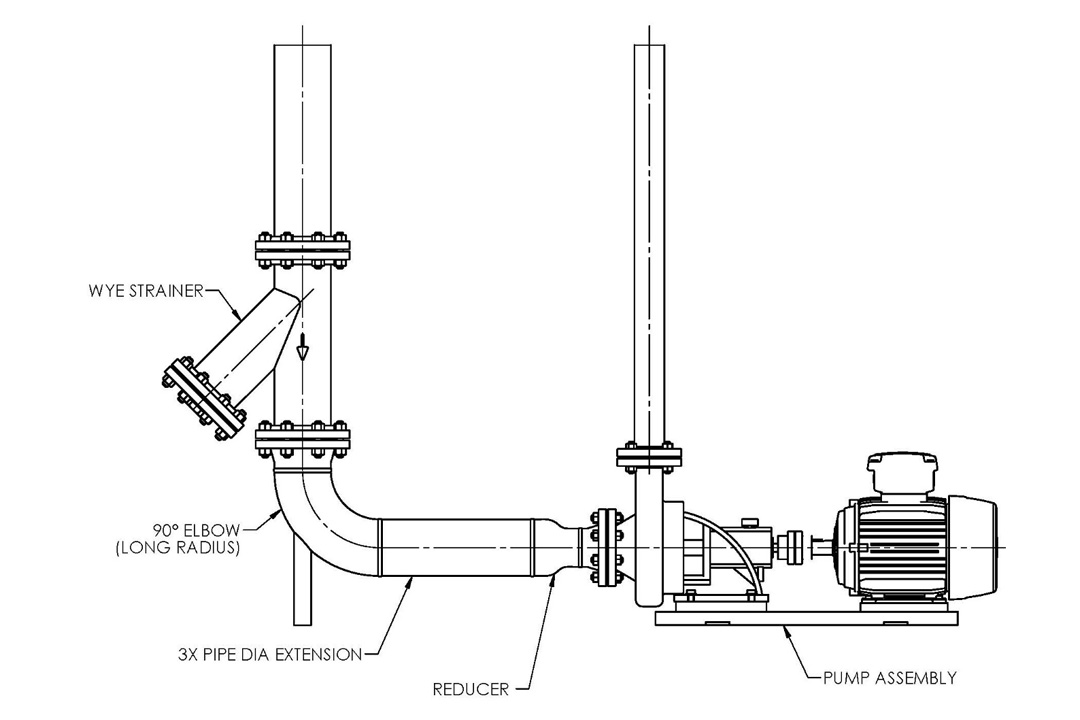

But when water enters into a pump directly from an elbow or short reducer, it can also start a swirling action that can have severe effects on the pump itself, wearing out seals faster and creating high imbalance within the pump itself. One way around this is to install a length of straight pipe going into the pump, but depending on the environment or application, available space may be at a premium.

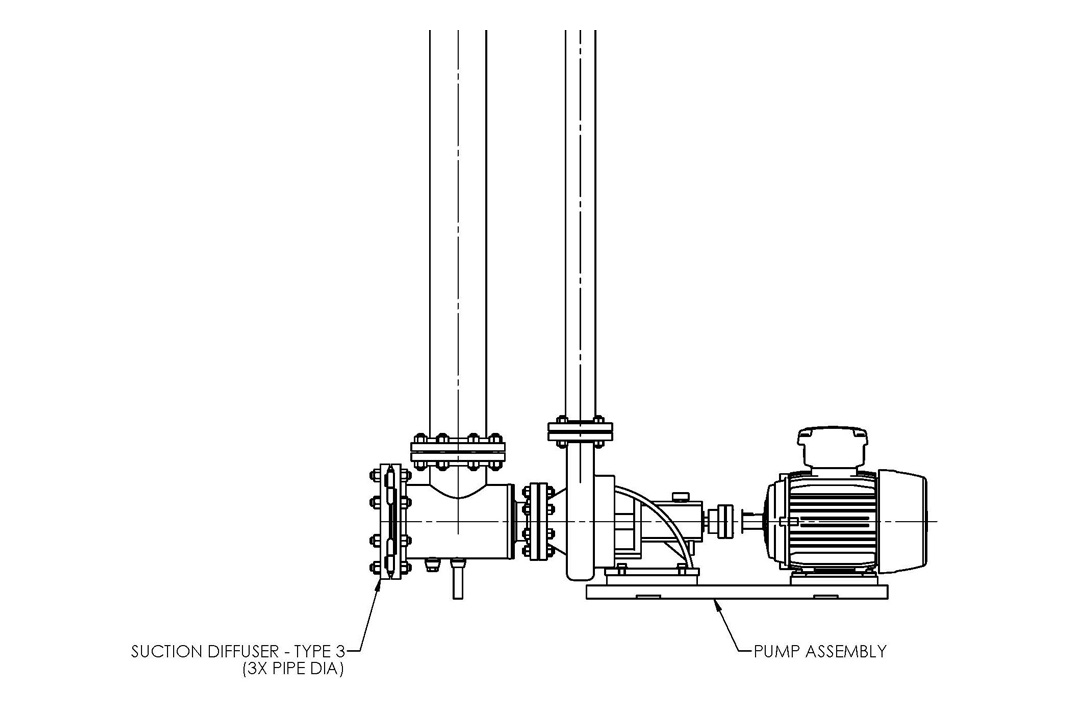

A suction diffuser solves both of these problems. The unit uses strainer technology to capture particulates before they enter the inlet, and also contains straightening vanes that prevents the swirling effect of water at the inlet, removing turbulence and protecting seals from wearing out quickly without the need for an additional length of straight pipe.

Further Details

- Filtration down to 40 microns

- Pressures to 740 PSIG

- Temperatures to 800°F

- Vent and/or differential pressure connections

- Hinged or quick opening/operator-assisted covers

- Units manufactured to sizes and designs specified by client

- Data packages and MTRs available on request

- Standard, undersized or oversized outlet connections

- One, three or five pipe diameters of flow straightening

- Carbon Steel

- Stainless Steel

- Other Materials Upon Request

- Flat Faced

- Raised Face

- Buttweld

- ASME Class 150

- ASME Class 300

- Welders certified to ASME Section IX

- ASME “U” stamped vessels available on request