Energy Recovery Module designed to recover energy from the hot lubricating oil from an Air Compressor. As part of the compression process the majority of input energy is converted to heat which is dissipated into the compressor lubricating oil circuits.

The Recovery Module is able to ‘recover’ the available heat from the lubricating oil, via a plate heat exchanger within the compressor. The heat is dissipated into a water circuit which is then used to heat process water used within the clients food manufacturing and wash-down processes.

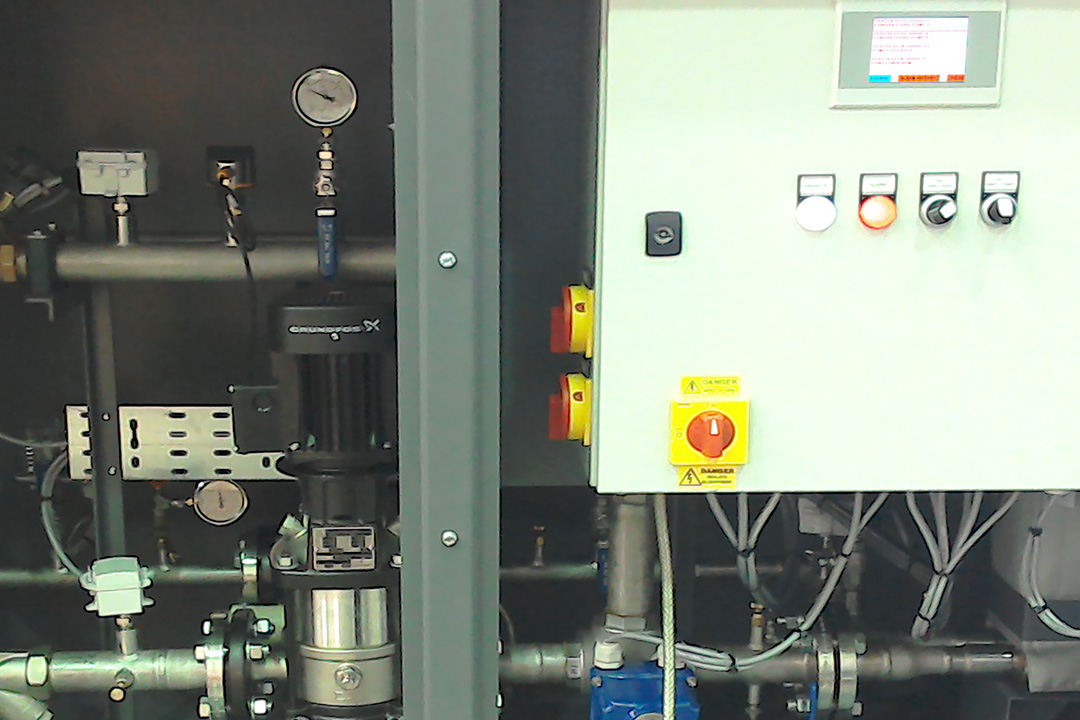

The Module includes Primary/ Secondary Circulation Pumps, Brazed Plate Heat Exchanger, Temperature Transmitters, Flow Transmitter.

The Digital User Interface displays all transmitter values as well as the amount of energy being recovered.