Time Served Experience and Innovation...

We have recognised that the reliability and efficiency of a successful Oil Recirculation System requires it to fulfil key functions, including: lubrication, filtration and cooling.

Lubrication

Supplying the appropriate quantity of lubricant at the required viscosity, temperature and pressure to a bearing or gear train to prevent failure.

Filtration

It is critical to remove contaminants such as dust, wear particles, water and other extraneous materials that build up during the operation of bearings and gear trains. The lubricant needs to be continually filtered to the correct cleanliness level prior to being recirculated. Denco Fluid Systems ‘Design and Support Teams’ work closely with customers, component suppliers and lubricant manufacturers to ensure our Oil Recirculation Systems achieve the system performance levels required.

Cooling

By maintaining the system oil temperature and flow rate at the required parameters, the heat generated by the motion and load of bearings and gear trains is removed, ensuring that lubrication is provided at the optimum performance level.

Complete Design Solutions

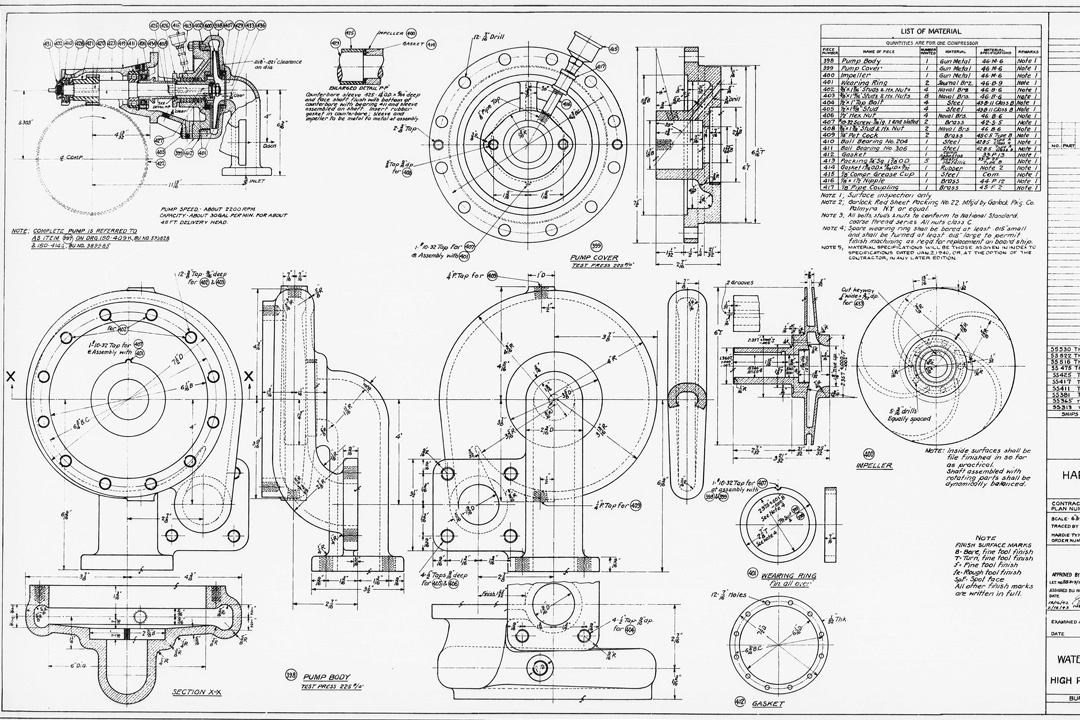

We pride ourselves on our ability to deliver the complete engineered design solution. Using the latest CAD technology our innovative design team work together to bring your specifications to life.

Through the use of technical drawings, 2D and 3D modelling, our designers ensure all specifications are met with precision without ever compromising the systems efficiency or the manufacturing process. With over 70 years commercial experience our dedicated team can cater for any set up requirements and will guide you every step of the way from concept through to completion.

Typical System Parameters

|

Suitable for Mineral Oil

|

|

|---|---|

|

Applications

|

Industrial & API

|

|

Oil Viscosities

|

Up to and incl. 680 cSt @ 40 °C

|

|

Oil Flows

|

1 to 2000+ LPM

|

|

Maximum Pressure

|

20 Bar+

|

|

Motor Power

|

Up to 75 kW

|

|

Voltage

|

380 / 400 / 440 / 460 / 480 V

|

|

Phase

|

Single & 3 Phase

|

|

Frequency

|

50 Hz / 60 Hz

|

|

Filtration

|

Simplex & Duplex: 3, 6, 10, 16 & 25 Micron – absolute and nominal ranges

|

|

Oil Coolers

|

Shell & Tube and Plate

|

|

Monitoring

|

Level, flow, pressure, temperature switches, transmitters and visual

|