Overhead Crane Gear Lubrication

Overview

Previous Lubrication of a leading steel manufacturers Overhead Crane Drive Gears was carried out manually, which led to overspill, waste and dangerous working areas. Oil was applied to the application, which regularly ended up on the floor, on the product or on the crane track. It was a health and safety matter so something had to be done.

You can see from photos that initially the open gears were deluged in oil, but it wasn’t long before they could be running dry, between maintenance visits.

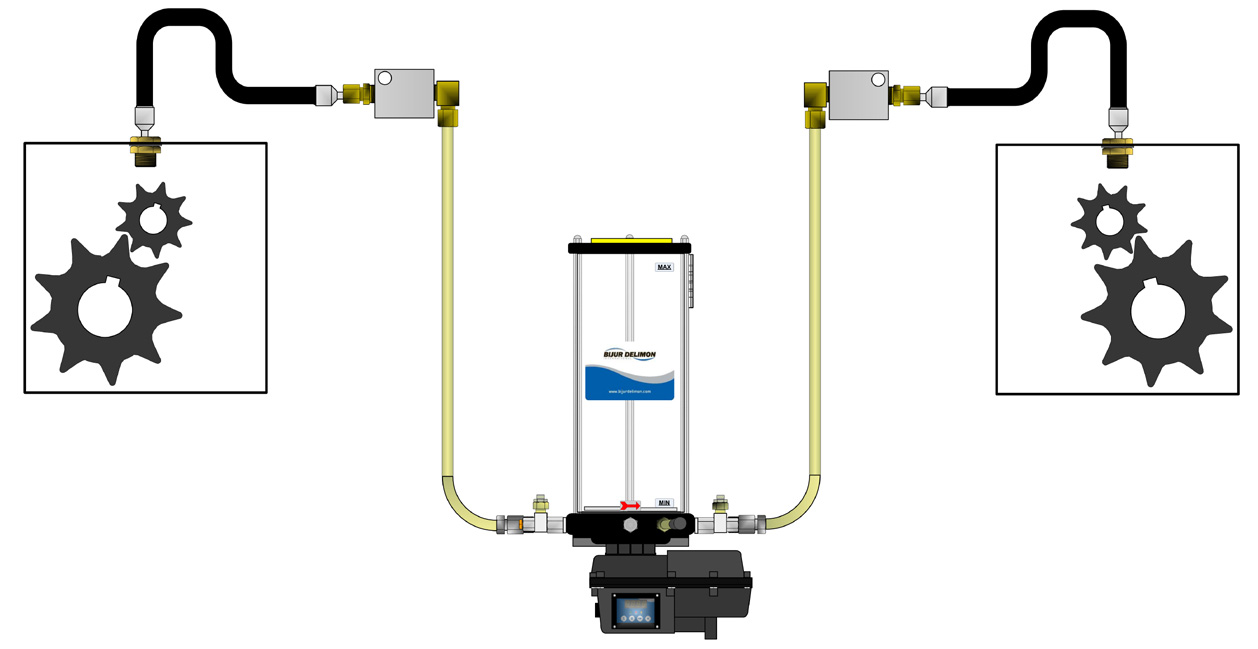

As can be seen, the gears are now proportionately oiled, with minimised wastage, and this solution has eradicated spills to adjacent areas.

Denco Fluid Systems were asked to provide a regular, regulated and adjustable solution to the problem. The Bijur Delimon Multiport II cycles continuously for up to 8 weeks between refilling (twice that of the labour intensive monthly manual lubrication regime), and uses significantly less lubricant due to the new adjustable controller conveniently integrated into the lubricator.

Challenges

The customer requested that the lubricator is top filled, as opposed to the traditional bottom filling of the lubricator. With the consequences of potential contamination explained and best practice guidance provided to, and, understood by the customer, this special Multiport II model is equipped with a unique top fill connection.

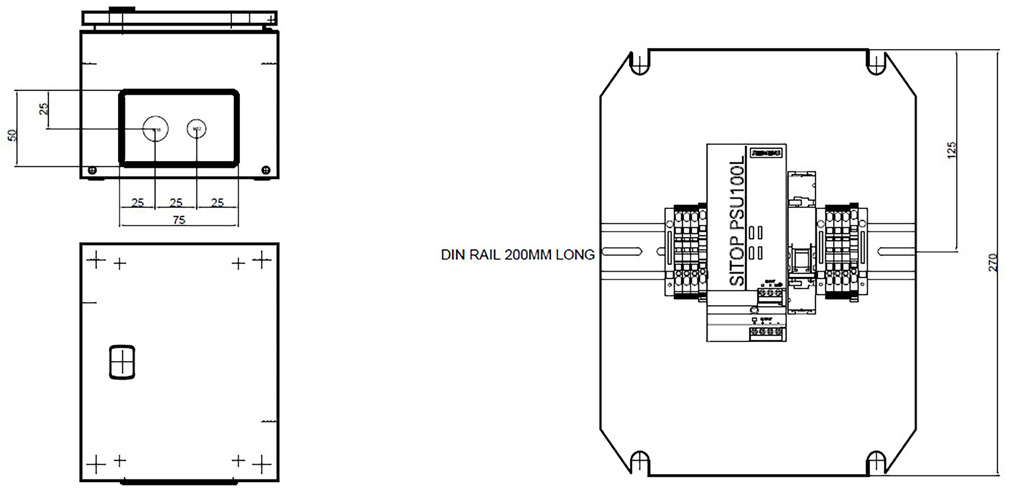

The customer could only supply 110v AC power and so a compact, cost effective power transformer is supplied with each system providing the 24v DC power required to the Multiport II.

These engineered solutions are provided by the team at Denco Fluid Systems.

The client has a number of applications across it’s multiple sites and Denco Fluid Systems are only too pleased to provide yet another solution.

|

Item

|

Description

|

|---|---|

|

1

|

Multiport II Lubricator

|

|

2

|

12mm OD Brass Tubing

|

|

3

|

Brass Compression Fittings

|

|

4

|

Anchor Blocks

|

|

5

|

Flexible Hose for Final Connection

|

|

6

|

Power Transformer

|